There are a variety of different uses for stainless steel. Parts made of stainless steel can be simple or very complex in shape, and they are found in all types of applications from aerospace and automotive parts and components to use in electronics, appliances, and equipment.

Stainless steel is an ideal material for many applications due to the corrosion-resistant nature of the material as well as the ability to stand up in both high and low temperatures. It is also a material that has a good strength to weight ratio, which is another reason it is so popular.

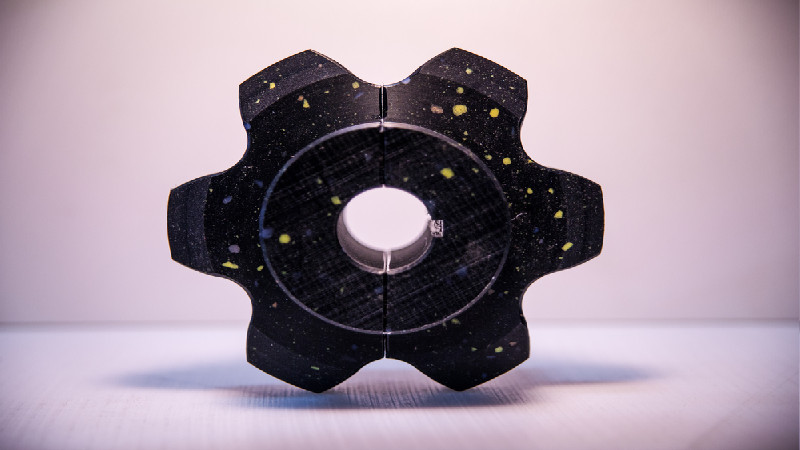

These parts can be formed in many different ways. Some are created by machining, which involves the use of cutting tools to remove material from a workpiece to create the desired internal and external shape. Another option is by fabricating individual pieces and welding them together. A third option, and one that is cost-effective and precise is the use of stainless steel stamping.

The Process

The process of stainless steel stamping does not require heating the metal sheet, so there is no need to provide additional stress relieving methods after the part is produced. As the part is made from one solid piece, there is also no weak areas, eliminating the problems associated with the welding of stainless steel.

Instead, stainless steel stamping uses high tonne presses that force the room temperature stainless steel sheet through a die. This die creates the shape, and it can be a very complicated and even asymmetrical shape.

For more complex shapes, a series of die may be used to progressively shape the final part. As this is a completely automated process, it is a very effective option for high volume production requirements. New technology allows for precision within and between orders, making stamping a leading consideration for OEMs across a range of industries.