When it comes to sanitary processing systems used in pharmaceutical manufacturing, food and beverage production and in specialized types of processing systems, VNE is a recognized name.

VNE fittings, valves, tubing, and specialty fabrications are found throughout the world in both small and large sanitary processing facilities. They are designed and manufactured to provide maximum durability, reliability, and safety, making them an ideal option for any type of sanitary process.

The company makes a range of different options in their VNE fittings lines, each which meets 3A requirements for sanitary processes. Each of the specialized fitting types are developed for various features and applications, and there is a difference to consider when making a choice.

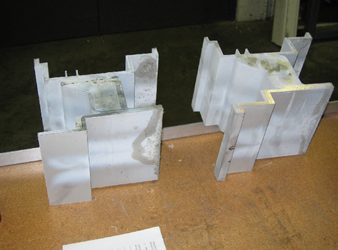

Weld and Clamp Fittings

The weld VNE fittings are the ideal option when there is a permanent installation for the system and a Clean In Place (CIP) process is used. These are fittings that are welded in, so they should not be used for systems that have to be removed for cleaning.

For lines and systems that have to be frequently broken down for cleaning or configuration, the clamp fittings are the best option. These fittings use a clamp to hold the fitting in place, which also makes removal and rebuilding quick and easy.

Bevel Seat

For components of the system that need to stay secure, rigid and in-place without any movement, the bevel seat fittings from VNE are the best option. These fittings have a union that is made by the mating of two different ferrules. The fittings can be used with or without a gasket, with both options providing full and shut-off.

In use for decades in systems of all types around the world, VNE has the fittings and the valves that are built to last. They also provide unpolished fittings that are ideal for systems where a sanitary valve is not required.