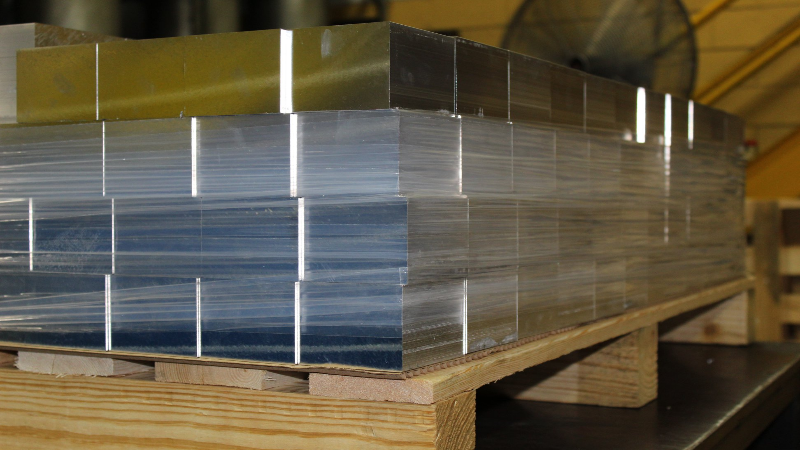

Extruded aluminum bars are useful in various industries, from construction to prototyping. If your company needs specially-designed aluminum parts, it could be right for you. The aluminum extrusion process allows for the custom design of metallic parts. So, it’s widely used in research and development, too.

How Do Aluminum Extrusion Companies Process Metal?

Each time an order begins processing, custom dies fit onto the extrusion machine. Then, an aluminum block gets forced through the die by a powerful ram.

It’s analogous to forcing everything out of a tube of toothpaste. As it exits the tube, its final shape gets determined by the exit’s opening.

What Kind of Shapes Can You Make With Extruded Aluminum?

Generally, extrusion machines design bars using several shapes. An angled bar looks similar to a right triangle, complete with a 90-degree angle.

Channels resemble the letter U, two walls with a central floor. Finally, a round extrusion is what you’re thinking about when you see a tube.

It’s also possible to design them using hollow or solid bodies. If there’s a need for added strength, solid parts tend to provide better results. However, it does cost more to produce them.

How Does the Extrusion Process Work?

First, the die is cast and placed into the machine. Then, the aluminum block gets heated before entering the processing chamber. Once there, it’s loaded onto the extrusion press. That’s where the ram forces it out through the die. In the end, it’s quenched, receiving a uniform cooling.