Aluminum extrusion can be quite versatile. It is also a heat-dependent process in which the aluminum alloys are then shaped into unique cross-sectional profiles. There are a variety of angles and profiles that can be included.

The key to custom extruded aluminum is to have a supplier that can meet your needs. Custom aluminum extrusion can be a complex process and trusting it to just about anyone is not necessarily the best idea.

The Benefits to Custom Extrusion

If you are wondering why your business might need custom extruded aluminum, there are reasons aplenty. For starters, it comes much closer to the final shape and can reduce both the purchase weight and the overall amount of machining required to bring it to that finished size.

Results of custom extrusion can include a faster manufacturing process, which can cut down on the amount of wasted material. It can lead to more consistent production and total proprietary control over your own designs.

The Customization Process

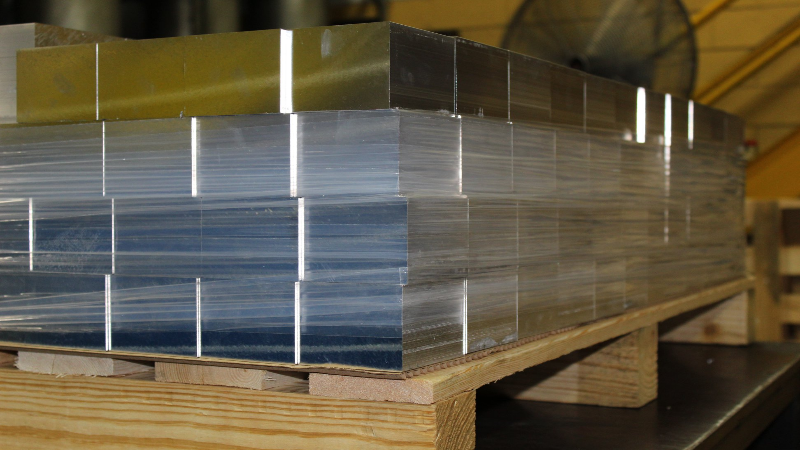

Creating customized extruded aluminum means creating a custom die that offers a cross-sectional profile. The material is then shaped when it gets pushed into the opening of the die, which takes on the profile of the die opening.

Extrusions can also be fabricated with holes as well as any other feature that might become a benefit to the manufacturing process. For complex designs, it means using high-grade aluminum and creating products that are close to the necessary tolerances.