The parts that you use in your shop for fixing cars can come to you in a variety of conditions. Especially if you use pre-owned or salvaged parts, you may need to have them conditioned to make them easier with which to work.

Rather than devote time and manpower to this task, you can hire an outside service to anneal and treat them for you. These reasons are some to invest in automotive heat treating for your mechanic and repair shop today.

Pliability

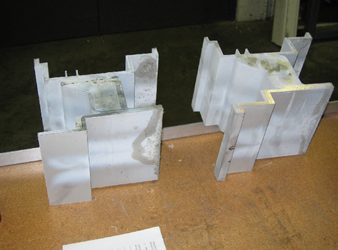

One of the main reasons to use this service involves making the parts more pliable with which to work. If the parts are fresh off the manufacturing line or reconditioned, they can be difficult to use in repairs on clients’ cars. You risk breaking, cracking or chipping them if they are too brittle or hard.

To make them more pliable, you can first send them to a service to have them annealed for you. The annealing service can make the metals in the parts softer and more flexible. At the same time, it can cool off the parts slowly to make them more durable and ideally suited for use in your customers’ car repairs.

When you use this automotive heat-treating service for your metal parts, you minimize or eliminate the risk of the parts breaking while you use them. You can make repairs quickly and use parts that you know will hold up well over time.