Believe it or not, aluminum is actually a rare metal in its native form and was considered to be more precious than gold or silver during most of the 19th century. Today, however, aluminum is a common material utilized by several industries like aerospace, manufacturing, electronics, and more. Perhaps you may have heard the term aluminum extrusion and wondering what it is. Here is a brief explanation of what it is, the 3 main categories of aluminum extrusion shapes, and what they are typically used for.

Aluminum Extrusion

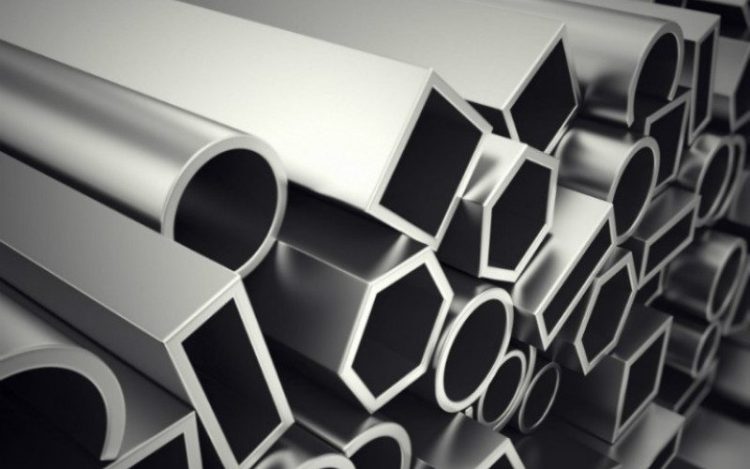

Aluminum extrusion is a process utilized to make or create objects. The process involves pushing or molding aluminum through a die with a specific cross-sectional profile.

Solid

Now that you know what aluminum extrusion is, you might begin to wonder about the types of shapes that are made using the process. Solid is one of the main extrusion shape categories. Aluminum beams, rods, and angles fall under this category. Aluminum solids can be found in applications that make fuel cells, industrial equipment, window frames, and more.

Hollow

Another main category of aluminum extrusion shapes is hollow. Hollow is a type of aluminum extrusion shape that consists of one or more voids. Square and rectangular tubes generally make up this category, though hollow circular tubes are also included. Like solid-shaped aluminum, hollow-shaped extrusions are used to also make industrial equipment, window frames, molds, and other similar objects.

Semi-Hollow

Semi-hollow is another main type of aluminum extrusion shape. Semi-hollow is a shape that consists of a partially enclosed void such as a “C” channel with a narrow gap. This shape is typically used in applications involving electronics, structural moldings, automotive, and more.